Resource Hub

How a Modern Technology Ecosystem Is Reshaping Rail Asset Management

Revolutionising Rail Maintenance: How Trapeze EAM and a Next-Generation Technology Ecosystem Are Shaping the Future of Asset Management

Modern rail networks are under pressure to do more with less. In Malaysia and across Southeast Asia, growing passenger volumes, expanding rail networks, and rising service expectations are pushing the rail industry to innovate. At the centre of this transformation is Enterprise Asset Management (EAM), which is fast becoming the backbone of smarter, data-driven maintenance practices. Sustainable maintenance now hinges on intelligent technologies, AI, predictive analytics, and fully integrated asset platforms.

Why the Status Quo Is No Longer Sustainable

Across Southeast Asia, and especially in Malaysia’s urban transit landscape, rail operators are grappling with ageing infrastructure, talent shortages, and increasing pressure to deliver world-class uptime and reliability. Traditional maintenance regimes often reactive, siloed, and resource-intensive are no longer sufficient.

Rail operators across this region are increasingly aligning with these global best practices. Smart maintenance initiatives within major urban transit projects are adopting IoT sensors, AI analytics, and centralised data hubs to streamline infrastructure performance.

“By leveraging AI, machine learning, and deep learning, organisations can reap several benefits, including predictive maintenance, intelligent decision-making, remote monitoring, and enhanced productivity.” PwC Belgium

The Shift Toward a Proactive, Data-Driven Approach

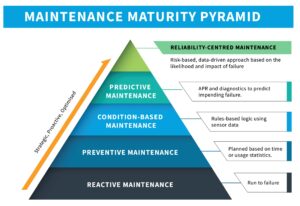

Rather than reacting to failures, forward-looking operators are embracing Enterprise Asset Management (EAM) platforms as the digital backbone of their rail operations. These platforms don’t operate in isolation they integrate data from across the network, enabling condition-based, predictive, and even prescriptive maintenance strategies.

“Modern EAM systems are evolving into integration hubs, linking artificial intelligence (AI), Internet of Things (IoT), and asset lifecycle data in one ecosystem.” Railway Gazette

The ASEAN Digital Masterplan 2025 and UNESCAP Strategy 2030 are also pushing regional governments and operators toward adopting these smarter asset strategies.

From Insight to Action: The 5 Pillars of an EAM-Powered Rail Ecosystem

With the urgency to modernise now evident, what follows is a practical framework to guide transformation. The five pillars below are intentionally structured to reflect the logical progression of maintenance maturity, from visibility to foresight, root-cause resolution, informed action, and ultimately, simulation. Each pillar is elevated through integration with the broader technology ecosystem, with Trapeze EAM at the centre.

- Asset Monitoring

Real-time monitoring of asset conditions provides the foundation for predictive analytics. Integrated tools like SCADA (Supervisory Control and Data Acquisition) continuously collect data from sensors and field equipment across the network. When connected with Trapeze EAM, this data becomes immediately actionable, feeding into dashboards, triggering alerts, and enabling maintenance teams to intervene before faults escalate. This integration allows rail operators to shift from static inspections to a dynamic, always-on monitoring model that ensures rapid fault detection and reduced manual workload.

- Asset Predictive Maintenance

Predictive capabilities use AI and ML to interpret sensor data and forecast potential failures. By identifying disruption risks before they materialise, rail networks reduce unplanned downtime and extend asset life, while making smarter use of limited maintenance resources. Now is the moment for predictive maintenance to take centre stage. The convergence of affordable sensors, scalable cloud infrastructure, and maturing AI algorithms means that rail operators can predict faults and degradation patterns with unprecedented accuracy. Trapeze EAM connects to platforms like Azure IoT to capture these signals in real time, enabling intelligent scheduling and automated intervention. The result: fewer service disruptions, safer operations and longer-lasting assets.

- Asset Reliability

For ASEAN operators managing rapidly expanding networks under cost and reliability pressure, reliability engineering provides a way to build resilience into infrastructure from the ground up. Through integrations with Failure Reporting, Analysis, and Corrective Action System (FRACAS) and Failure Modes and Effects Analysis (FMEA) tools, Trapeze EAM allows teams to trace failure modes, assess root causes, and implement long-term engineering controls. It’s not just about fixing faults, it’s also about eliminating them from the future.

This proactive loop helps standardise best practices and fosters a culture of continuous improvement within rail maintenance teams.

- Asset Intelligence

Trapeze EAM compiles and curates the data that matters, turning it into meaningful intelligence. Rail-specific dashboards such as Mean Time Before Failure (MTBF) by asset class, work order mix, compliance heatmaps, lifecycle cost metrics, and team productivity analytics give Malaysian operators a comprehensive, real-time view of performance. These insights inform better decisions at every level, from daily maintenance execution to long-term capital planning. Thanks to Trapeze’s architecture, these dashboards are always powered by clean, accurate data drawn directly from field operations.

- Asset Virtualisation

In an era of high-density urban rail and limited engineering access, being able to plan and visualise virtually is game-changing. Trapeze EAM’s integration with Building Information Modelling (BIM) and Digital Twin platforms enables scenario simulation, virtual site inspections, and remote design collaboration. Operators can explore maintenance plans, assess access risks, and test engineering solutions without shutting down a line or stepping into the field saving time, cost, and risk. By uniting these technologies under the EAM umbrella, teams have one central command hub to coordinate and rehearse interventions before executing in the real world.

Maintenance Maturity Journey – From Visibility to Virtualisation

The maintenance maturity model illustrates how each of the five pillars aligns with a strategic phase in rail modernisation. Starting with asset visibility and condition monitoring, each step builds on the last from data collection and predictive intervention to root cause elimination, strategic intelligence, and ultimately, virtual planning and simulation. By following this sequence, operators can scale transformation at a sustainable pace, unlocking measurable impact at each stage.

EAM as the Heart of Modern Rail Maintenance

Unlike generic asset platforms, Trapeze EAM is purpose-built for rail. This means deeper integration, industry-specific workflows, and alignment with the unique demands of modern networks. From high-usage rolling stock and linear assets to complex infrastructure and round-the-clock availability.

With features designed around the real-world needs of maintenance managers, Trapeze EAM streamlines task execution, provides real-time visibility, and ensures critical information flows across the organisation. This leads to measurable improvements across the board:

| Key EAM Benefit | What It Means in Practice |

|---|---|

| Improved asset availability | Maximised uptime and fewer delays during peak travel periods |

| Lower lifecycle maintenance costs | More efficient use of parts and labour, reducing total cost of ownership |

| Faster fault response | Real-time alerts and mobile workflows accelerate repair times |

| Optimised crew and inventory use | Smarter scheduling and parts forecasting reduce waste and improve productivity |

| Compliance tracking and mitigation | Automated audit trails and safety checks support regulatory compliance and risk management |

Preparing for What’s Next: A Roadmap to Modernisation

Digitalisation in rail is no longer optional, it’s mission-critical. As AI, IoT, and cloud-based systems become the norm, integrating these technologies within a unified EAM framework is essential to maintaining control, agility, and competitive advantage.

Here’s how to begin the journey:

- Define operational goals: Set clear success metrics whether that’s improved uptime, reduced cost, or enhanced workforce productivity.

- Select the right EAM: Choose a solution engineered for rail, not retrofitted from another industry.

- Partner for progress: Collaborate with a provider who understands your environment and can evolve with your needs.

Trapeze EAM in Action: What Rail Operators Gain

With Trapeze EAM as the digital heart of operations, rail agencies aren’t just keeping pace, they’re setting the pace. An EAM like Trapeze’s brings together critical maintenance, operational and asset data into one intelligent, centralised platform. It enables real-time visibility across asset classes, facilitates predictive interventions, and streamlines coordination between teams, systems and technologies. This convergence of data and function transforms strategy into execution, empowering rail operators and their maintenance teams to act with confidence, agility, and foresight.

We also understand that transformation doesn’t happen in a vacuum. That’s why Trapeze collaborates closely with both global technology leaders and local ASEAN innovation partners. Whether operators are already working with international vendors or need tools tailored to local standards, our platform is built for flexible, compatible integration.

Let’s Build the Future of Rail Maintenance – Together

The rail industry is undergoing a profound shift toward smarter, more agile, and deeply integrated operations. And at the centre of it all is Enterprise Asset Management. Trapeze EAM empowers rail operators to transform maintenance from a reactive burden into a proactive advantage cutting costs, boosting reliability, and laying the tracks for long-term sustainability. Let’s work together to modernise your infrastructure, elevate your teams, and build a more reliable, resilient rail network.

Ready to take the next step?

Let’s explore how a purpose-built EAM, combined with an integrated technology ecosystem, can deliver measurable improvements across your network. Reach out to book a tailored consultation or request a live demo and discover what’s possible with Trapeze.

Mode of Transport

Rail

Solutions

Enterprise Asset Management